Rather watch than read? Check out the video 👇 which has the same story as this post but with a rare opportunity to luxuriate in my monotone baritone as I narrate my way through a prudent selection of pictures and drone footage.

The pond aka the marsh

The pond started as a gravel pit in the front yard.

For many years it was an excellent resource. We took out dozens of truckloads of gravel which we used to build all of the driveways on the property. There’s no finer gravel than the gravel that doesn’t cost a dime.

However useful the pit has been, by 2024 it had overstayed its welcome. You can only look at a strip mine in your front yard for so many years before the sight starts to sour. What to do about this crunchy eyesore? Well, we could turn the pit into a pond. That might work.

Most people would use an excavator for this type of project but my dad had a different idea. He chained himself to his D21A Komatsu bulldozer and pushed the dirt out.

By his reckoning the project required moving some 1,500 yards of material, equal to more than three million pounds. No small feat! By late summer, after nearly six months of dirt work, my father had the rough shape of the pond excavated.

With a bulk of the heavy moving done it was time to finetune our approach. We took a transit, found the high water mark of the pond (where it would overflow its banks first) and then made marks all around the perimeter.

We used the marks to marks to draw an orange line that showed the shape of the pond. This gave my dad an idea of where he should take out more dirt, or add dirt back in. He wants some of the land to become exposed during the summer. He’s also trying to create a non-uniform shape so that the pond looks like it formed naturally.

In fine dining it’s an open secret that the more exquisitely shaped the food, the more it’s been manhandled. A meatball sandwich from the local diner might not look like much but it’s only been in the chef’s hands for about six seconds. The same idea applies to dirt work. The more natural and irregularly shaped a pond, the more it’s been finessed by things that run on diesel.

Once my dad is happy with the shape of the pond it’s time to take measurements for the pond liner. We find a rough center of the pond by putting a stake at either end. We run a string between the two stakes, let it gently fall to the ground and that’s our center line to measure off of.

The composition of the liner determines the measurements we must submit. Most pond liner companies produce their product in 12’ wide rolls.

At the factory they cut the 12’ rolls to length and join the segments together with a 3’’ overlap.

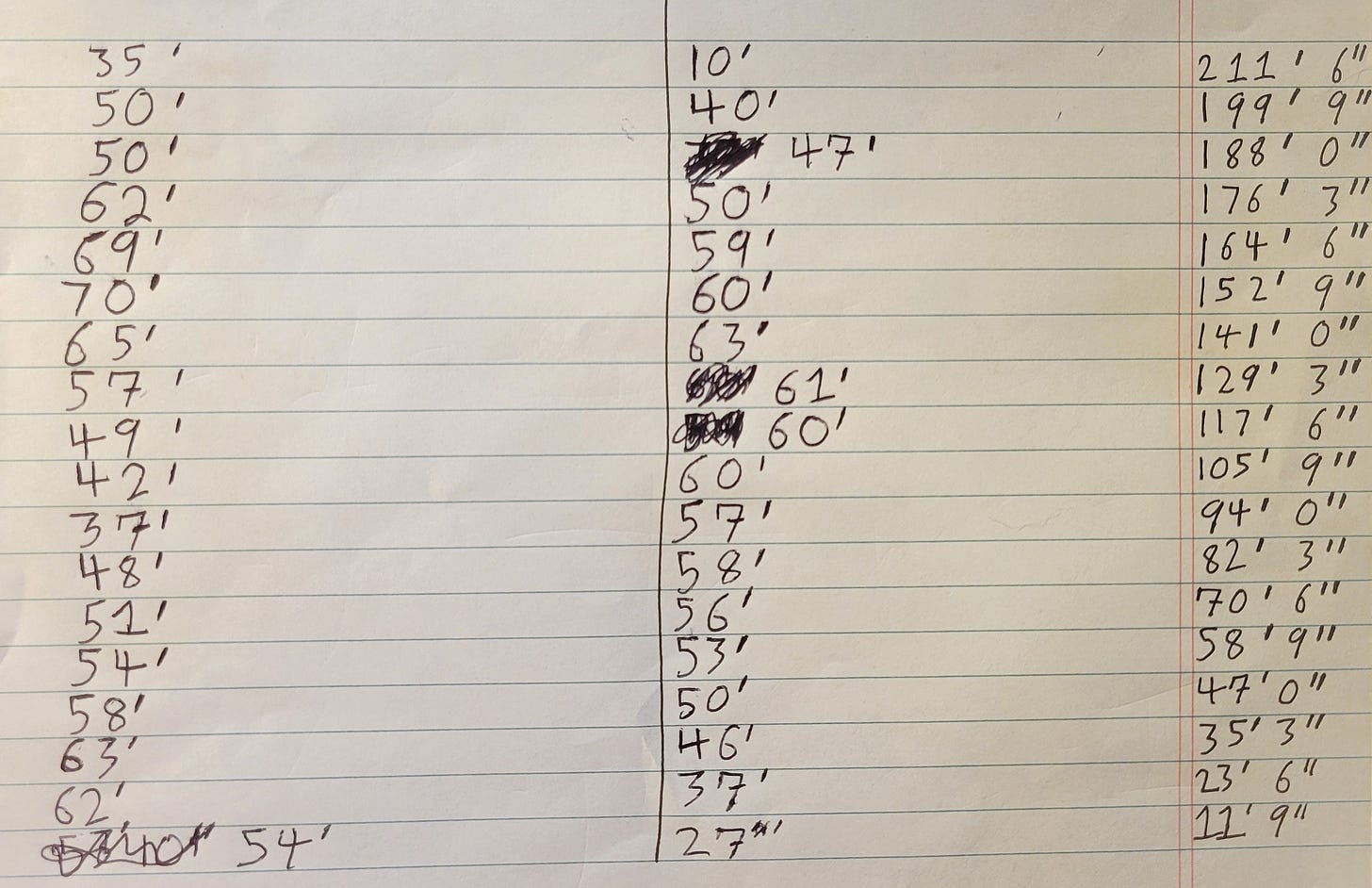

Because of that overlap the liner companies ask that you submit your dimensions in 11’9’’ increments. With that in mind our measuring process is,

Set up the transit exactly 11’9’’ from the first stake

Turn it 90 degrees to the left and measure how far we want the liner to extend from the center liner

Turn the transit 90 degrees to the right and repeat

Continue this process (for several hours) until we’ve measured the entire pond

Once completed the numbers look like this.

We gave the numbers to our engineer and he turned them into a drawing that shows the exact shape of the liner.

We sent our picture over to BTL Liners and they got to work on it. We ordered a 40 mil RPE liner which is supposed to be incredibly tough and should hold water for a number of decades.

Fast forward three weeks to the arrival of the pond liner and it’s time to call in reinforcements. A mini bulldozer and a 45 HP tractor aren’t going to carry us across the finish line, we’re going to need reinforcements. A John Deere 160G excavator and a 331G skid steer should suffice.

I was the excavator operator and I was impressed at how effortlessly this machine chucked thousands of pounds of dirt around. The bucket looks like it’s big enough to drive a four wheeler into! But even with a kiddie pool bucket the excavator punched holes in the dirt like it was digging through angel food cake.

Transplanting a small tree was a breeze.

With the trees out of the way we began a final round of excavations, clearing a path around the perimeter of the pond. Near the bottom of the bowl is our pump which we used to clear up a bit of water that had collected.

Even the dog is chipping in!

This is the final shape of the pond, just a few hours before we put the pond liner in.

To get rid of any rocks on the surface (so they don’t poke holes in the liner) we used a rockhound.

This skid steer attachment, also referred to as a landscape rake, has hundreds of small metal spikes on a conveyor system. You start them spinning and then drive the skid steer backwards. The spikes twirl around and throw the rocks into the bucket.

The rockhound is an effective tool that leaves a neatly groomed trail.

Once I’m done my dad goes over the whole pond with the roller, putting an end to any recalcitrant rocks that had resisted the rockhound.

The rocks are gone, now we just have to fetch the liner. It arrives conveniently located at the back of this trailer. The liner is so deep into this truck you can’t even see it. We had to jury rig four straps and a heavy chain to the bucket of the skid steer just to yank it out.

By the time we got it out (as traffic slows to a crawl) the excitement levels were running high and the pallet looked like Dresden after WWII.

After we cleared the power lines I could lift the liner into the air, which made it a lot easier to carry.

Up at the site we unwrapped the liner, discarded the ruined pallet and checked for holes. The liner looked fine! Do you see that white patch on it?

That’s the instructions. They tell us how far down the pond to place the liner, and the direction to unroll it in.

We measure the distance and use the transit to draw a 90 degree line. This is the line we’ll attempt to unfurl the liner on.

I move the liner into place with the excavator as my dad keeps it from swinging around too much.

We put the liner on the orange line and begin unrolling it.

We have about thirteen guys helping us spread it which is just barely enough. Another few gentleman would have been eagerly welcomed.

The liner is heavy!

But it’s not just the weight, the damn thing is slippery and hard to grip. All of us who aren’t wearing gloves end up with liner knuckle.

We learned the hard way that you need to get handles for this type of thing. That could be a pair of vice grips, of any other kind of gripping tool so that you’re not trying to wrestle with tough plastic.

Torn up knuckles suck but they’re worth it because the liner fits perfectly! All of our work with the transit has paid off. Our measuring tools might have been rudimentary but they proved more than adequate.

Plenty of people don’t cover their liners and that’s fine, but there’s no way we want to look at this black plastic for the next seventy-eight years. More dirt must be moved!

We can use the excavator around the perimeter of the pond but it’s too heavy to drive onto the liner. We’re going to use the skid steer for 90% of the fill in.

We start with a single road and expand from there. The skid steer weighs 14,000 lbs. with a load of dirt in the bucket but it has wide rubber tracks and we don’t think we’re going to puncture the liner. We aim to cover everything with one to two feet of material.

After ten days of mostly good weather, and about 150 gallons of diesel (skid steers are dieselholics), we have a majority of the liner covered. I never thought that I’d get sick of driving a skid steer but this project has shown me that it’s possible. Navigating in the mucky parts of the pond, where water has already started to collect, is demoralizing hell.

That being said, we both agree that the John Deere is a fine machine, far superior to the Bobcat we rented last year. The JD is easier to get into, the door to the cab opens when the bucket is raised, it’s faster and the cab is quiet enough that you can listen to the radio. We’ll never get another Bobcat if we can help it.

This 331G in particular was a mind scrambling beast. For trail making I was able to put the tip of the bucket down, lift the front of the machine into the air and backdrag backwards up a steep hill at full speed. How much torque does it have? Yes…

Once the skid steer has dumped the material we smooth out the surface with a rake on the back of the tractor.

The good weather continues and within two weeks the entire liner is out of sight and the pond has started to fill. Success!

That was an awful lot of work, and it’s not done yet either. Next year we’ll go do another sculpting to get the perfect shape we want around the perimeter. But now it’s November and winter is setting in. We got the work done just in time, a job well done.

The pond is a dirty mess right now but by next summer it’s going to look fantastic. If you’re not already a Garden State subscriber and you’d like to follow its progress please subscribe right here 👇 more to come!

Wow- Impressive work. And to boot it’s very pretty to look at